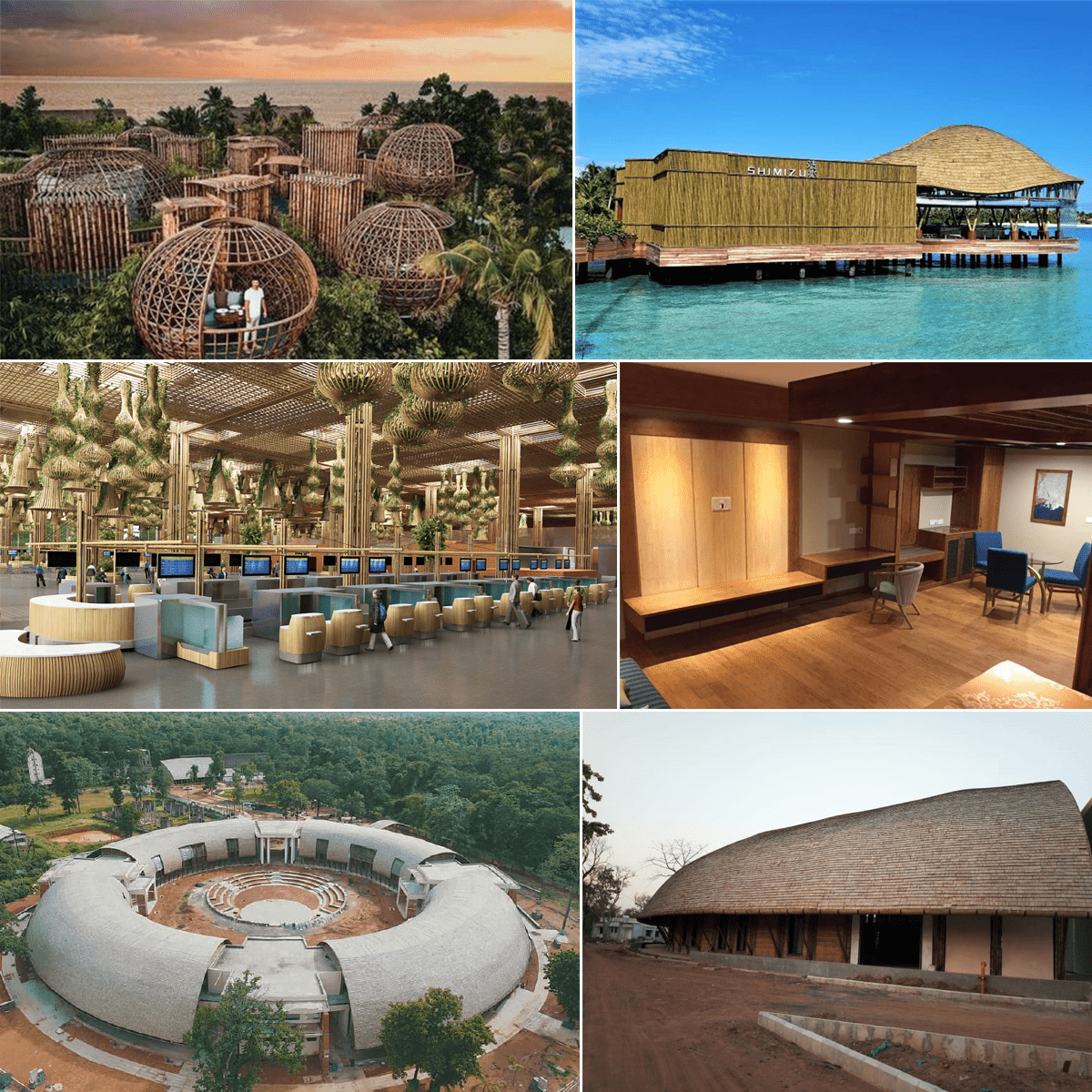

Bamboo has been in use for flooring, kitchen surfaces, doors, and chopping boards. Bamboo, a native plant, is commonly used as a structural material and as scaffolding in some parts of Asia and South America. Today, with more countries looking towards natural building materials, bamboo will play a very major role to reducing future carbon emission. The 2020 Global Status Report for Building and Construction states that buildings account for 28% global emissions while construction-related industries such as cement, glass, etc. add another 10%. It is time for a culture shift within the construction industry to provide sustainable buildings or green buildings. It is time to transform the best architectural designs to include bamboo as an engineered product. Bamboo is the material of the future for the construction industry - it is the green steel of the 21st century! Why is bamboo sustainable building material? It is time to grow our construction material. Bamboo is an environmentally friendly plant. It is fastest replenishing material and can be recycled and repurposed. Not any bamboo, but species like Asper, Balcooa, Guadua, stocksii and Tulda are among the few dozen species suitable for the construction industry. Here are a few reasons why sustainable architects in India and around the world are combining Western engineering with the potential of Eastern bamboo. 1. Tensile strength Bamboo has higher tensile strength than steel on weight-to-weight basis because its fibers run axially. It possesses a natural capacity to take high-tensile force. It can withstand up to 3656 kg/cm2 of pressure. 2. Fire Resistance Bamboo has silicate acid in its skin and the water content in its body that makes it fire retardant 3. Light weight Bamboos being light, are easy to transport and install as compared to materials like steel. Architects are searching for materials like bamboo to use in sustainable building designs and eco-friendly home designs. 4. Renewable Bamboo is a ‘renewable’ agroforestry resource harvested within 3-5years. It has a remarkable growth rate, high-yield, can re-stabilize eroded landscapes, and store the highest amount of carbon, than any other plant. Remember, while 500 hectares of timber forest is needed to produce 1000 houses, only 60 hectares of a bamboo plantation can yield the same result. Treated Bamboo also has a lifespan between 30 to 100 years. 5. Health and safety Bamboo in construction does not pose any danger to health.Firstly it is easy to use with lesser tools and machinery, and secondly, it does not have a negative impact like asbestos does on one’s lungs. 6. Earthquake zones With a positive strength-weight ratio and its elastic feature, bamboo becomes a highly resilient material against forces created by high-velocity winds and earthquakes. Eco-friendly architects of India are studying bamboo homes as a better option in earthquake-prone areas and damp tropical climates. 7. Fewer emissions Bamboo needs a lower emissions-intensive process to create components for the construction industry. It only consumes 1/3rd, 1/8th, 1/50th energy vis-a-vis the requirement to process timber, cement, and steel. Disadvantages of bamboo in construction The industrial framework for bamboo in construction is still in its infancy. Other constraints come in the way of accepting bamboo as a construction material of the future. These include social awareness, government rules and regulations, lack of easy accesses to preservation and standardization, and inequitable supply. Bamboo also requires care and attention during its growth cycle. To use bamboo as a building material, it requires different works while still growing like a plant. They include Splitting, Shaping, and Bending to create the desired shape, structure, and length for structural bamboo. Bamboo has played a vital role in creating rural homes but has a limited role in its foundation. It is more suitable for skeleton, walls and roofing.

There are also significant other disadvantages that experts are working on to establish the role of bamboo. For bamboo to become a global construction material, the dimensions to be taken into account are its Durability, Jointing, Flammability, Cracking and splitting, and Design and Codification of Bamboo.

1. Durability Structural strength and durability are the most crucial factors. Especially with high-rise towers, the bamboo must qualify as durable and structurally safe for the construction industry.

2. Jointing The jointing system gets difficult while working with bamboo because of its shape. There is plenty of research undertaken to overcome this problem and develop jointing systems for effective structural load distribution and transfer.

3. Flammability Bamboo does represent a high fire risk when the skin of the bamboo stem that creates silicates is sanded for a smoother look for the interiors of a building. There are traditional practices such as filling the cavities with concrete, adding paneling, or plastering over bamboo elements to retard fire, but it will require more attention if it has to be successfully used as an eco-friendly building material of the future.

4. Cracking and Splitting It is necessary to understand the function of bamboo poles in the completed structure. Since cracking and splitting of the bamboo can affect the overall strength of the building structure. Multiple drillings and tightening of bolts may result in cracks in the vertical fibers. Similarly, bamboo can split due to tension, compression, flexure loads in bolted connections, and drying.

5. Design and codification Eco-friendly architects in India use a tool known as Digital Image Analysis (DIA) to determine fiber distribution in sections of the bamboo. It helps them to design with a fair degree of accuracy once they ascertain the elasticity of bamboo. Lack of standardization leads to more design efforts on the part of the architect working with bamboo. Also, an absence of adequate codification makes the material difficult to assess.

Conclusion The usage of bamboo is still nascent in India’s INR 6 trillion (USD 89.2 billion) construction industry. From Kerala’s houseboats to Assamese homes, it has to find a way to our living and working spaces through more diverse and the best architectural designs. While technological and industrial advancement in bamboo-based construction has started in other parts of the world, including countries like China, Vietnam and Indonesia, it will be some time until it is an inevitable part of India’s living architecture and construction industry. Its planned development demands attention and joint efforts of the government, builders, architects, and environmentalists. India being the second-largest producer of bamboo in the world, has a long road ahead.

Till then contact a home remodel architect near me, to dream your future eco-home!